Quick change flexible line

High precision and fast adjustment

Parts traceability

Solve problems at source

Personnel error-proofing management

Ensure production safety

6 New Energy Product Production Lines Flexible, Efficient and Quality-assured Production

Process error-proofing management

Improve production line efficiency

Torque control management

Ensure finished product quality

Production record file preservation

Effective management of the entire production process

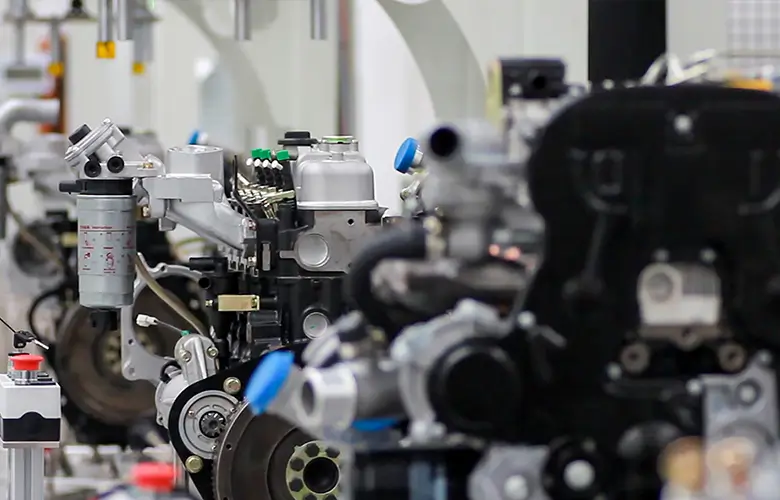

Our Manufacturing

MOREDAY uses the latest technology and electrical manufacturing equipment to fully realize production automation, and the factory introduces the 6S management system to realize order delivery visualization. We are able to fulfill high-volume orders with excellent production speed, while notably ensuring the quality of the products we produce. Our fully automated assembly lines ensure you are equipped to handle periods of high market demand.

Custom Mold

Automated Assembly

Traceable Production

Production Visualization

Our Manufacturing Advantages

Reduced labor costs

Automated factories require fewer workers than traditional factories, reducing labor costs significantly. By replacing manual labor with machines, companies can produce more goods with fewer employees. This reduces the need for labor-intensive processes, such as assembly lines, thereby reducing the number of employees required to produce the same number of products.

Improved efficiency

The use of machines in factory manufacturing improves efficiency. Machines can produce goods faster and more accurately than manual labor. This reduces the time taken to produce goods, thereby increasing productivity. Moreover, machines can work around the clock, making it possible to produce goods even after working hours. This translates into increased production capacity and faster delivery times.

Consistent quality

Automated factories produce goods of consistent quality. Machines are programmed to perform the same task repeatedly, ensuring that each product is identical. This eliminates the possibility of human error, which can occur during manual labor. Moreover, automated factories have quality control systems that check the products for defects, ensuring that only high-quality goods are produced.

Cost-effective

Factory manufacturing is cost-effective. The use of machines reduces labor costs and improves efficiency, resulting in a lower cost of production. Moreover, automated factories can produce goods in bulk, resulting in economies of scale. This means that the cost per unit reduces as the number of units produced increases. This makes it possible for companies to sell their products at a lower price, increasing their competitiveness in the market.

Customizable

Factory manufacturing is customizable. Machines can be programmed to produce different products, making it possible for companies to produce a variety of goods. This makes it easier for businesses to meet the needs of their customers, as they can produce goods in different sizes, shapes, and colors.

Reduced lead time

Factory manufacturing reduces lead time. Lead time is the time taken from when an order is placed to when the goods are delivered. Automated factories can produce goods faster than manual labor, reducing the lead time. This means that companies can deliver goods to their customers faster, resulting in higher customer satisfaction.

Sustainability

Factory manufacturing is sustainable. Machines produce less waste than manual labor, reducing the environmental impact of the production process. Moreover, automated factories consume less energy than traditional factories, resulting in lower energy bills. This makes factory manufacturing an environmentally friendly option for businesses.

Improved safety

Automated factories are safer than traditional factories. Machines can perform dangerous tasks that are hazardous to human workers. This reduces the risk of accidents in the workplace, resulting in a safer working environment.

Better inventory management

Factory manufacturing improves inventory management. The use of machines reduces the time taken to produce goods, resulting in faster replenishment of inventory. This makes it easier for businesses to manage their inventory levels, ensuring that they have enough stock to meet customer demand.

Scalability

Factory manufacturing is scalable. Automated factories can produce goods in large quantities, making it possible for businesses to expand their operations. This makes it easier for companies to meet the increasing demand for their products, resulting in increased profits.

Of course, Moreday’s factory has a full set of system certifications, and it is also a Chinese green factory.

Everyone is welcome to visit the Moreday factory, our production is visualized, and we look forward to your suggestions.

The Moreday factory is a relatively advanced modern factory that has realized most of the product production automation.

What Our Partners Say About Us

Moreday has won praise from many consumers through its high-quality products and friendly services and continues to contribute to the sustainable energy development of the world.

Rhett Brown

“MOREDAY’s solar products and charging pile products are great! I became their agent. Their charging piles are highly innovative and reasonably priced. I am very satisfied with the service of MOREDAY, their technicians are professional and solved my problem in time. I will promote the MOREDAY brand in our country!”

Richard Crown

“After being forced to move twice within five years, our customers had a hard time finding us and our sales plummeted. Moreday not only revitalized our brand, but saved our nearly 10-year-old family business.”