Previous

Next

2.5MM 4MM 6MM 10AWM 12AWM 14AWM SOLAR CABLE

2.5mm2 4mm2 6mm2 10awm 12awm 14awm for solar dc system

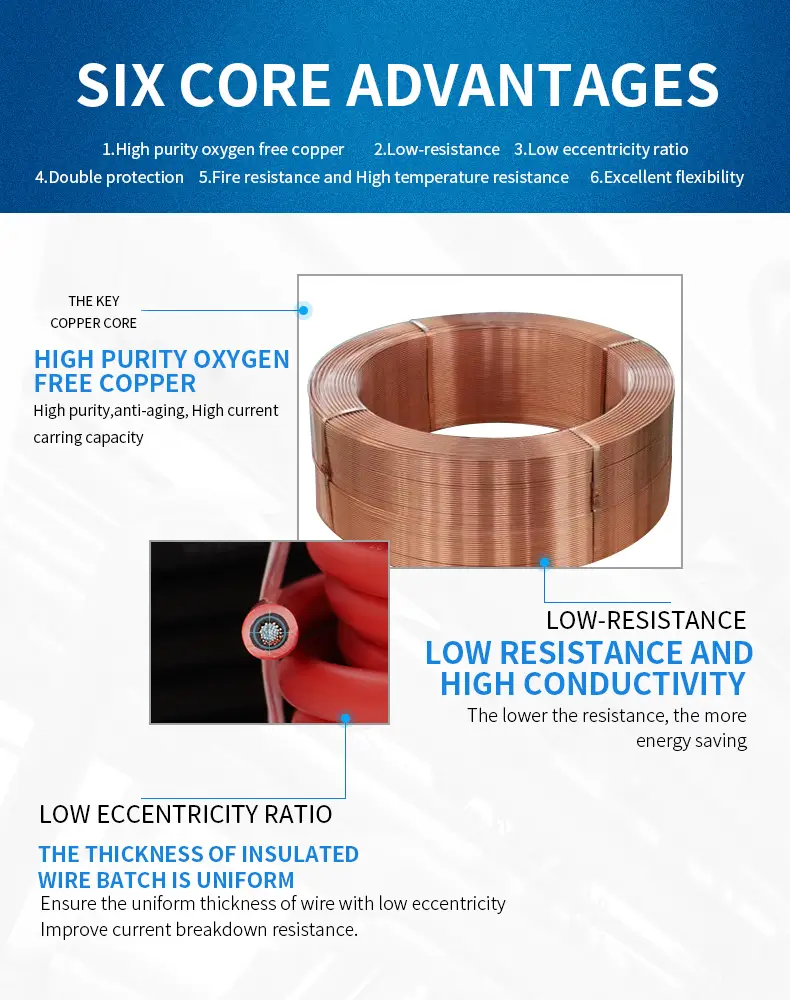

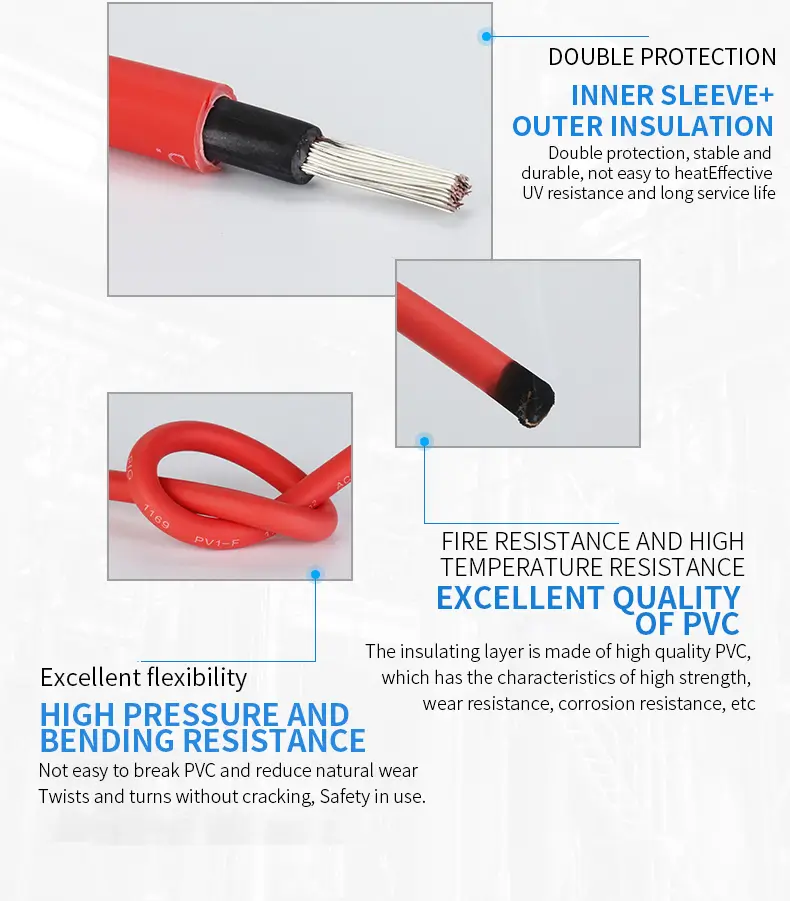

Features:

- 100% tinned copper reduces loss

- Good flame retardancy, weather resistance, UV resistance and temperature resistance

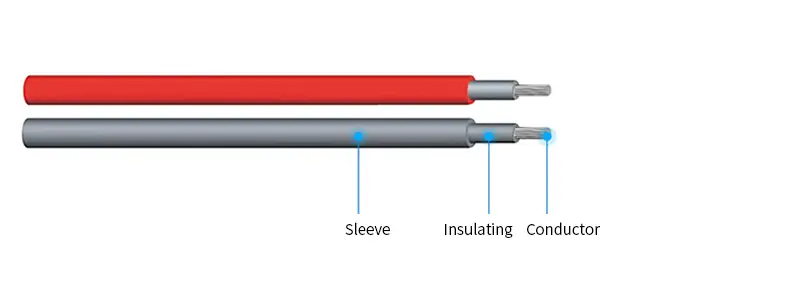

- Double insulation for harsh outdoor environments

- Long service life

- RoHS material